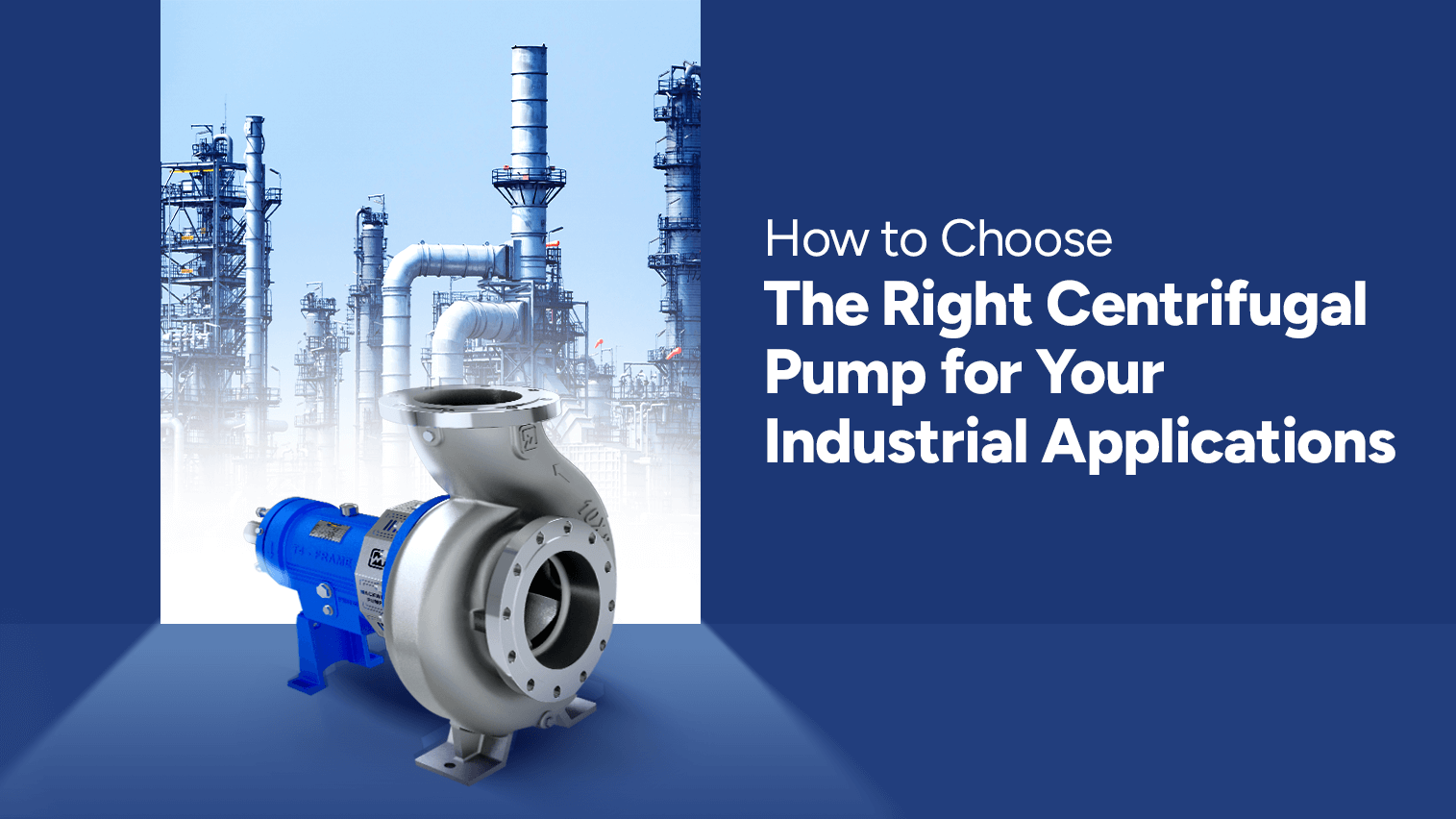

Choosing the Right Centrifugal Pump for Oil Transfer Applications

Oil transfer, either crude, refined, or chemically processed, is not the time to be sloppy when selecting a pump. The room for error is narrow. It gets hot. Liquids may be toxic, flammable, or corrosive. This is where Mackwell Pumps can help.

Centrifugal Pump Manufacturers in India are durable, reliable, and efficient under pressure. It should be your checklist when making the comparison. And there is one name that keeps on ticking off the list: our MACKPRO Centrifugal Pump, a high-performance, robust pump specifically designed to take on abrasive liquids in the oil and chemical processing industries.

Let us stroll through what is essential when selecting a centrifugal pump to transfer oil, and why MACKPRO is the best in all respects.

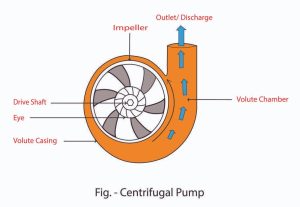

Why Centrifugal Pumps Are Ideal for Oil Transfer?

Centrifugal pumps: Fluids are moved by kinetic energy, so this type of pump will fit well in continuous and high-volume oil flowing systems.

- They have an extensive viscosity range, which is ideal for various kinds of oil.

- Less maintenance implies an abridgement of the downtime and operational expenses.

- Adaptable to hot places and chemically unsafe surroundings.

1) Fluid Compatibility is Non-Negotiable

Different oils are different. Others are delicate and gentle. The others are thick, corrosive or even abrasive. The pump has to suit the fluid.

- MACKPRO is constructed to handle toxic, flammable and damaging fluids.

- It has more than 30 hydraulic combinations, which help it fit well to your fluid properties.

- Open design impeller. The open impeller design works with solids and minimises clogging.

2) Temperature Range Matters More Than You Think

The transfer of oil does not always take place under climatic control. The heat ranges are extreme hot to sub-zero, according to the needs of the process.

- MACKPRO works at temperatures between -50 °C and +260 °C without tail-off.

- Designed to accommodate abrupt temperature variations, it would not develop expansion gashes or overload fatigue.

3) Pressure & Flow Rates: Balance is Key

It is not the capacity at the highest- it is the performance at the rate required that must be maintained.

- Provides up to 1590 m 3 /h (7,000 GPM) flow.

- Supports siphon head pressures to 223 meters (730 ft) and can be used in vertical and long-distance transfers.

- This can remain efficient irrespective of varying loads and speeds.

4) Mechanical Strength and Longevity

The mechanical properties were tested with the help of a computer. With oil applications, any other leak will lead to great problems. The pump should be tough and secure in extreme working conditions.

- MACKPRO is in ANSI/ASME B73.1 regulations.

- FC150 flanges are used according to standard Class 150 FF secured and industry-approved connections.

- Built in severe conditions and run on continuous duty.

5) Easy Integration into Existing Systems

You do not want to redesign the whole system to accommodate one pump. The compatibility is all.

- Standard piping and motor setups fit well with MACKPRO.

- It is small, strong, and a space saver for old and new plants.

What Sets MACKPRO Apart?

As long as you are among the Centrifugal Pump Suppliers in India, you still struggle to select which one to opt for. Here are the reasons why MACKPRO will continually make it to the top of your list:

- More than 8 years of field-proven installation in chemical, petrochemical and refinery.

- Backed up by a complete package of spares and maintenance, keeping down the total cost of ownership.

- With engineers behind the scenes who are familiar with actual-world plant issues, rather than just specifications.

Access technical specifications of MACKPRO here.

How to Finalise Your Selection?

The proper pump selection should not be based on a specification but on the operation. This should be done as follows:

- Know your fluid: High viscosity? Any wear-and-tear material?

- Specify conditions of operation: The range of temperature, flow requirement, power available, and space available for installation.

- Look for standards compliance: ANSI/ASME, ISO, and material certifications.

- Demand serviceability: Enquire whether the supplier provides after-sales services and the availability of spare parts.

- Think about the long term: Pick a safe, efficient and expandable solution.

Still unsure? Refer to this guide from Pumps & Systems Magazine for an external perspective on selection parameters.

MACKPRO At Work: Industry Use Cases

- Chemical: Where strong chemicals associated with processes are shifted in high pressure reactions.

- Refinery System: When you move the crude oil through different processes of cracking and separation.

- General Manufacturing: Pumping, cutting fluids, oils, and coolants. It circulates cutting fluids, oils, and coolant mixtures through large-scale equipment.

Clients can trust MACKPRO because it works where other pumps cannot, particularly in areas with high heat, pressure, and chemical load levels.

Final Words

Selecting a proper centrifugal pump is not a technical issue but primarily strategic. Downtime, fluid loss, overheating or low efficiency happen and may cost you more than money. We are not pump sellers but performance, safety, and peace of mind engineers at Mackwell Pumps.

In search of the best Centrifugal Pump Manufacturers in India, or the Centrifugal Pump Suppliers in India, and when comparing these Centrifugal Pump Suppliers in India, MACKPRO should be your first call, and probably your last visit.

We can make your oil transfer system smarter, faster and safer. Connect now.

FAQ’s

1) What makes centrifugal pumps ideal for oil transfer?

They effectively move large quantities of fluid with low viscosity and cope with temperature differences.

2) Can MACKPRO handle abrasive or dirty oil?

Yes, the open impeller structure handles particulates without blocking, making it usable in semi-processed fluids.

3) Is MACKPRO suitable for explosion-prone environments?

Absolutely. It is safety and industrially designed and used in flammable liquids.

4) How do I get a price quote or technical datasheet?

You may order it on our official product page here.