Comprehensive Guide to Centrifugal Pumps: Benefits, Applications, and Key Specifications

Picture operating chemical plant or refinery, with time being paramount. There is just one thing standing between you and downtime: pump.

That’s why selecting the right partner from Centrifugal Pump Manufacturers isn’t a matter of specs, it’s about ensuring your operations are safe.

Here at Mackwell Pumps we have experienced first-hand how the correct centrifugal pump revolutionises processes. Let’s take a closer look at what makes centrifugal pumps so important, where they are applied and why our FLOWELL™ and MACKPRO™ ranges are used globally.

Why Centrifugal Pumps Are Essential?

If you’ve ever wondered why centrifugal pumps are everywhere, the answer is simple: they combine efficiency with adaptability.

- They can move large volumes of liquid at steady pressure

- Their designs suit both clean and contaminated liquids.

- They keep operating costs under control by reducing energy wastage.

Centrifugal pumps are non negotiable in industries where safety, performance and reliability matter.

Key Benefits You’ll Appreciate

- Versatility: From refineries to chemical plants they adapt to varied conditions.

- Cost-Effectiveness: Minimal maintenance and energy savings.

- Reliability: Continuous operations without frequent shutdowns.

- Longevity: They are made to withstand corrosive fluids and physical stresses.

And if you choose the right pump from reliable Centrifugal Pump Suppliers, these benefits get doubled.

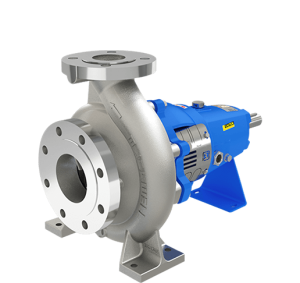

FLOWELL™ Centrifugal Pump: Versatility Meets Precision

Visualize FLOWELL™ as the performance and versatility converging pump.

- Fabricated according to ISO 2858/EN 22858 standards.

- Does away with slightly contaminated, clean, and even toxic fluids

- Capacity of up to 1500 m³/h with heads up to 160 m.

- Handles extreme temperatures ranging from -50 °C to +200 °C.

FLOWELL™ is in its element in chemical, petrochemical, and general industries where consistency is crucial.

Learn more about FLOWELL™ at Mackwell Pumps

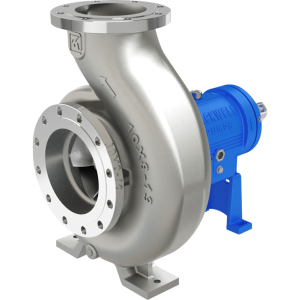

MACKPRO™ Centrifugal Pump: Built for the Toughest Jobs

Now, if your operations demand strength under extreme conditions, MACKPRO™ delivers.

- Meets ANSI/ASME B73.1 specification.

- Moves up to 1590 m³/h at heads reaching 223 m.

- Operates at high temperatures up to +260 °C.

- Rugged design with an open impeller for enhanced efficiency.

In refinery systems and harsh chemical industries, MACKPRO™ thrives where others fail.

Applications Across Industries

You’ll find centrifugal pumps in almost every industrial sector. Let us mention a few:

- Chemical and Petrochemical: Handling toxic and flammable liquids safely.

- Refineries: Running in high temperature and pressure conditions.

- General Industry: From cooling water systems to process applications.

- Pharmaceuticals: Precise liquid transfer with safety at its core.

A centrifugal pump is part of the solution wherever a liquid can move.

Specifications That Matter

When choosing your pump focus on:

- Capacity: FLOWELL™ up to 1500 m³/h, MACKPRO™ up to 1590 m³/h.

- Head: FLOWELL™ handles 160 m; MACKPRO™ pushes up to 223 m.

- Temperature: From -50 °C for cryogenic uses to +260 °C for refineries.

- Pressure: FLOWELL™ works up to 16 bars.

These aren’t just numbers; they translate into real performance in demanding environments.

Industry Growth and Importance

Demand for centrifugal pumps is not abating. Fortune Business Insights indicates the global market will be worth USD 51.13 billion in 2030, propelled by chemical and industrial growth. This fact mirrors the daily reality: pumps are the backbone of industry today.

How to Pick the Right Pump for Your Needs?

Here is a convenient guide for your choice:

- Identify your liquid—clean, dirty, poisonous, or corrosive.

- Match flow rate and head requirements.

- Factor in operating temperature and pressure.

- Meet global standards (ISO for FLOWELL™, ANSI for MACKPRO™).

- Select a supplier who knows your market.

When you check all these boxes, the decision is easy.

Why Mackwell Pumps?

We don’t just design pumps, we create trust.

- Decades of expertise in pump engineering.

- Solutions designed for chemical, petrochemical, and refinery duty.

- Service that centers around you with a focus on making you smoother and safer to operate.

When companies think of long-term reliability, they think of Mackwell.

Final Thoughts

Centrifugal pumps are more than hardware they’re the heartbeat of your company. With FLOWELL™ and MACKPRO™ we welcome you to pumps designed to international standards, tested for lifespan, and trusted by companies worldwide.

Ready to choose the right pump for your operations? Explore our full product line at Mackwell Pumps!

FAQs

Q1: What makes centrifugal pumps better than other types?

They transport huge amounts of liquids with high efficiency and lower maintenance than the rest.

Q2: Can centrifugal pumps handle hazardous chemicals?

The appropriate materials and seal choices are appropriate for toxic or combustible liquids.

Q3: Which industries use FLOWELL™ and MACKPRO™?

Both are applied within chemicals, petrochemicals, refineries and general industry.

Q4: How do I know if I need FLOWELL™ or MACKPRO™?

Choose FLOWELL™ for versatility and MACKPRO™ for extreme conditions.