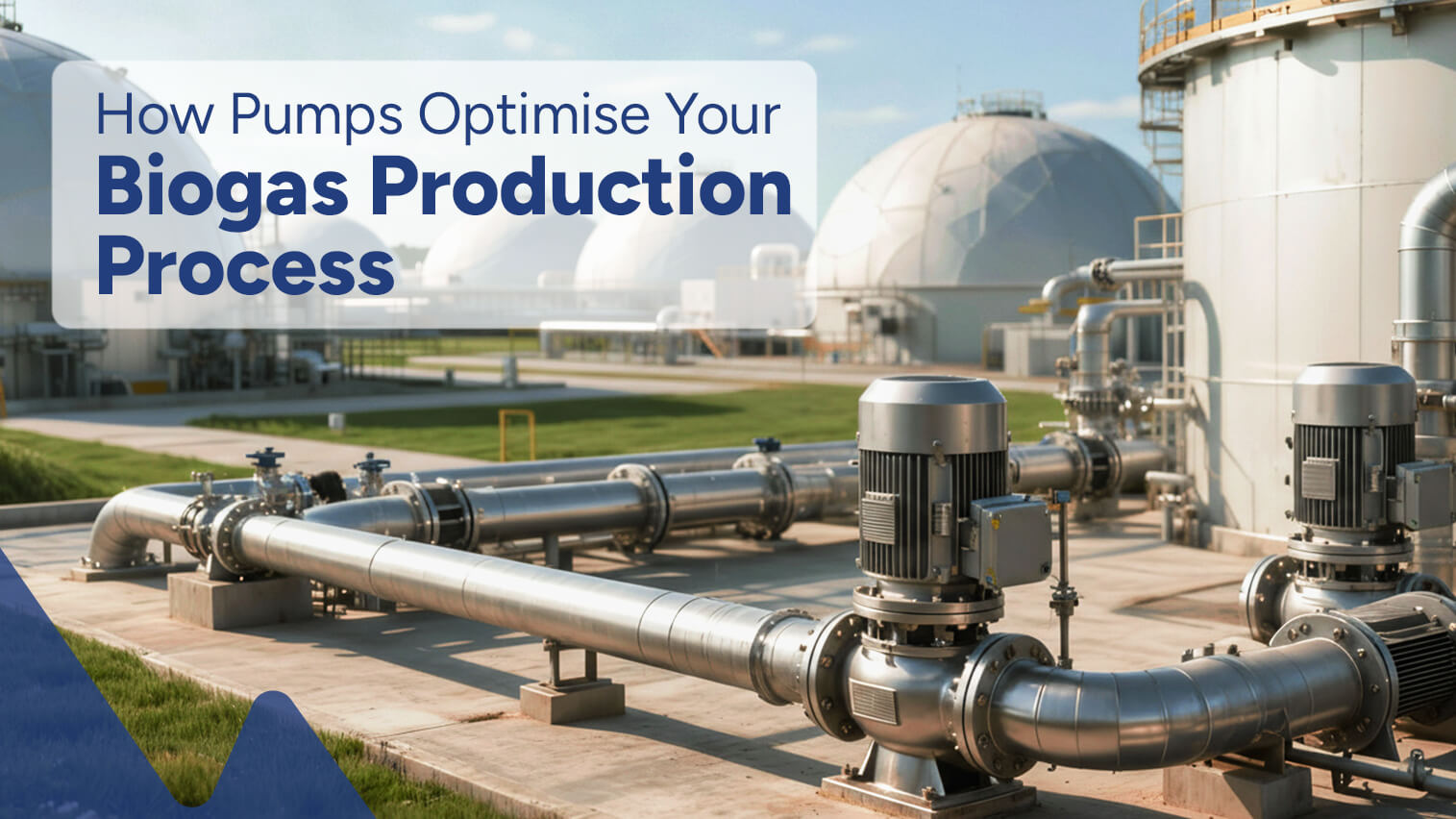

How Pumps Optimize Your Biogas Production Process?

You might be curious about what makes biogas plant running efficiently; most times, the pumps are what make it tick. They are biogas production process hidden heroes, making all stages function with accuracy, consistency and reliability.

At Mackwell we know that pumps are as important to sectors that require efficiency and security. As top industrial pump manufacturer in India, we create pumps that are not just machines but solutions specifically designed to manage tough applications.

Why Pumps Are the Heart of Biogas Plants?

Biogas generation is not so much fermenting waste material. It’s pumping slurry, circulating fluids and pressure maintenance through systems.

You risk downtime, contamination, or reduced output without the right pump. And when every cubic meter of gas counts, that’s the last thing you want.

Here’s how pumps make a real difference:

- They transport slurry between digesters and storage units.

- They circulate fluids at the right speed to ensure uniform digestion.

- They manage pressure levels for safe gas handling.

- They help maintain a consistent flow even when working with corrosive or toxic liquids.

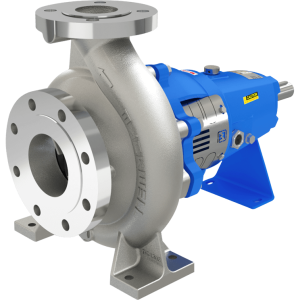

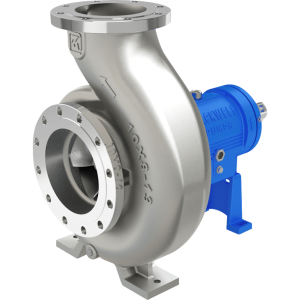

FLOWELL™ Centrifugal Pump – Precision for Everyday Flow

Our FLOWELL™ Centrifugal Pump is engineered for industries that need smooth operation without compromise.

- Designed to ISO 2858/ EN 22858 standards.

- Handles clean and slightly contaminated liquids with ease.

- Wide range of materials and sealing options for versatile use.

- Withstands hostile conditions with an operating temperature range from -50 °C to +200 °C.

Its delivery rate of up to 1500 m³/h and head of 160 m keeps your biogas slurry running continuously. It’s an all-rounder that balances performance and durability for general industry and chemical processes.

MACKPRO™ Centrifugal Pump – Built for Harsh Conditions

When your plant is handling toxic or flammable substances, the MACKPRO™ Centrifugal Pump is your best friend.

- Complies with ANSI/ASME B73.1 standards.

- Comes with an open impeller design for high efficiency.

- Handles up to 1590 m³/h capacity and a head of 223 m.

- Built to withstand harsh temperatures up to 260 °C.

Whether running an extensive refinery system or biogas setup with challenging fluids

MACKPRO delivers performance without compromise.

How Pumps Optimise Biogas Efficiency?

Biogas production is chain of connected procedures. Every stage needs fluid movement & pressure control. Pumps keep this chain unbroken:

- Better flow management- Smooth circulation means faster and uniform digestion.

- Less downtime- Pumps such as FLOWELL and MACKPRO are strong and withstand continuous working without frequent servicing.

- Energy Efficiency- Efficient pump minimizes energy consumption and caps operation expenses.

- Safe Handling of Liquids- When handling corrosive or toxic waste pumps safeguard the system and the workers.

The International Energy Agency (IEA) believes biogas can supply up to 20% of the world’s gas demand by 2040. But that’s only possible if plants optimise their processes with robust equipment like advanced pumps.

Why Mackwell Pumps Stand Out?

When we talk about pumps we don’t just mean moving liquids. We mean delivering reliability that supports industries day after day.

- Decades of expertise in fluid engineering.

- Products are tested to international standards.

- Wide product range covering multiple applications.

- Designed for long life, efficiency, and safety.

Explore more about our pumps here: Mackwell Pumps Products!

Key Benefits for Biogas Plants

- Reliability – Pumps that won’t quit when times get rough.

- Flexibility – Seal and material selection for any fluid.

- Efficiency – Higher output & lower energy expense.

- Safety – Built to handle dangerous flammable fluids.

- Longevity – Built to withstand harsh conditions.

Conclusion

The future of clean energy hangs in balance of how effectively we address all components of producing biogas. The pumps are tiny components of the equipment yet they are the strings that hold things moving along. Mackwell doesn’t just make pumps; Mackwell makes trust, efficiency and reliability for businesses that cannot be without downtime.

Whether the FLOWELL™ Centrifugal Pump with its precision engineering or the MACKPRO™ Centrifugal Pump designed for harsh, demanding conditions both are crafted to support plants in reaching their maximum potential.

As one of top industrial pump makers in India, we remain dedicated to assisting industries in realizing the potential of biogas. With the proper pumps, your plant isn’t just operating, it’s performing, safely and efficiently.

FAQs

Q1: Why are pumps necessary in the biogas production process?

They ensure smooth conveyance of liquids and slurry, maintain pressure, and secure processes.

Q2: Which Mackwell pump is best for biogas plants?

FLOWELL is excellent for general flow management, while MACKPRO is ideal for harsh conditions with toxic or flammable fluids.

Q3: Do the pumps accommodate very high temperatures?

Yes, FLOWELL has a temperature range of -50 °C to +200 °C, and MACKPRO to 260 °C.