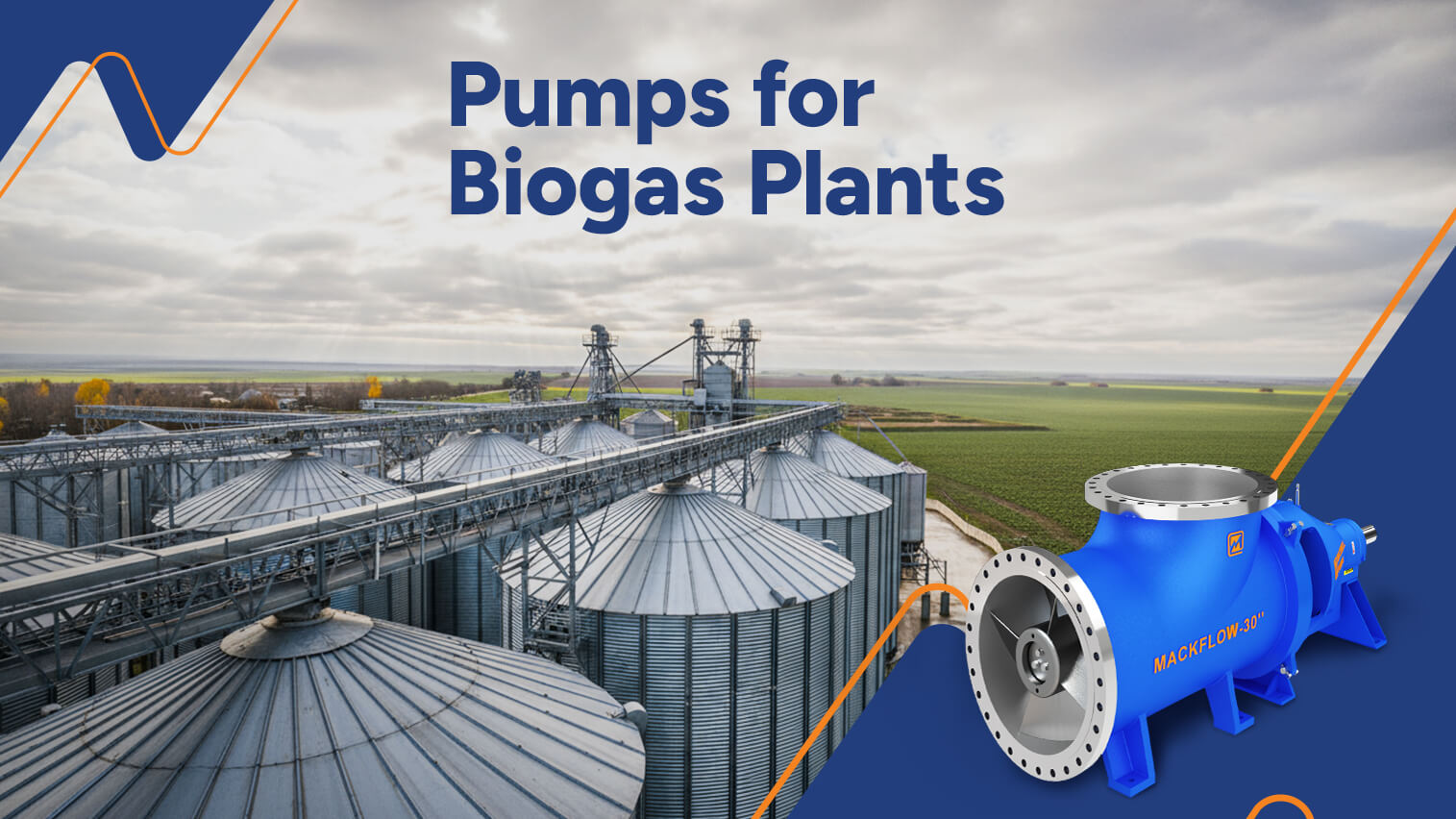

Pumps for Biogas Plants

The demand for renewable energy has put pumps for biogas plants at the heart of many industrial conversations. Why? Because without reliable pumping systems biogas facility can’t function efficiently. At Mackwell Pumps we’ve seen firsthand how right pump doesn’t just move fluids, it keeps the entire production line running smoothly, safely and profitably.

As one of India’s reliable industrial pump suppliers, we know that biogas production is not merely a matter of energy. It is a matter of precision, safety, and durability. Let us discuss why pumps play a vital role in biogas plants and how our FLOWELL™ and MACKPRO™ centrifugal pumps come into the equation.

Why Pumps Are Critical in Biogas Plants?

When we mention biogas plants, we immediately think of digesters breaking down organic waste matter. Yet between them is intricate network of fluid movement: slurry feeding, heating systems, recirculation and flow of digestate.

That is where pumps come in:

- They pump slurry into digesters without clogging

- They stabilize heating systems by ensuring hot liquids keep circulating

- They transport biogas residues to storage or additional treatment

- They transport corrosive and sometimes toxic liquids safely

Without the proper pump, your plant is exposed to downtime, contamination, or inefficiency. And in business where minutes matter that’s an exchange you can’t risk.

FLOWELL™ Centrifugal Pump

Our FLOWELL™ centrifugal pump is ideal for those environments where accuracy and versatility are key. It is manufactured to ISO 2858/EN 22858 standards and is an excellent option for biogas applications dealing with clean or lightly contaminated fluids.

Here is why FLOWELL™ functions so efficiently in biogas plants:

- Capacity: It has a capacity of 1500 m³/h and ability to handle high-capacity fluid exchange.

- Durability: Operates between temperatures of -50 °C and +200 °C, hence extreme temperatures are not concern.

- Material Flexibility: Material choices for chemically aggressive or corrosive fluids are included.

- Industries Proven: It is safely applicable for toxic and flammable liquids from the general industry to petrochemical plants.

The result is reduced shutdowns and predictable performance for biogas operators even when working with fluids that would ruin weaker systems.

MACKPRO™ Centrifugal Pump – Strength for Harsh Conditions

And where strength is MACKPRO™ precision is FLOWELL™. Built to ANSI/ASME B73.1 specifications, it performs in harsh, corrosive and high temperature conditions common in biogas processes.

What makes MACKPRO™ stand out?

- Performance: Maximum 1590 m³/h and maximum 223 m head pressure processing.

- Temperature: Optimal operating temperature range between -50 °C and +260 °C.

- Engineering: Over 30 hydraulic choices and open impeller design for greater reliability.

- Heavy Duty: Compatible with refinery systems and processes of hazardous liquids.

In biogas plants where digestates may be finicky and occasionally abrasive MACKPRO™ offers confidence.

How Pumps Optimise Biogas Plant Operations?

Let’s look at the real impact:

- Efficient Slurry Movement: Pumps help feed digesters at consistent rates.

- Stable Heating: Circulating hot liquids in pumps maintain bacteria in digesters.

- Residue Management: Wastewater digestate is transferred unimpeded.

- Long Term Cost Savings: Permanent pumps eliminate breakdowns and increase maintenance cycles.

The International Energy Agency (IEA) estimates biogas can be up to 20% of total gas demand by 2040 with sufficient infrastructure support. Pumps are quiet but integral element of turning that vision into reality.

Why Choose Mackwell for Biogas Pumps?

We don’t just build pumps at Mackwell we engineer reliability. With FLOWELL™ and MACKPRO™ you receive:

- International standard consistent pumps

- Proven performance in sectors where intricate and hazardous fluids are dealt with

- Experience from one of India’s foremost industrial pump manufacturers

- Long term dependability that saves your operations and downtime costs

When you purchase Mackwell, you’re not only purchasing pump but investing in operating your entire biogas plant.

Conclusion

In biogas pumps aren’t an afterthought — they’re lifeline. The appropriate system guarantees trouble free operation, increased energy returns and more secure fluid handling.

At Mackwell our FLOWELL™ centrifugal pump and MACKPRO™ centrifugal pump are designed to make biogas plants function optimally under the toughest conditions. You’re not just pumping liquids with us; you’re nearer to sustainable energy tomorrow.

FAQs

1. Why specialized pumps for biogas plants?

Because biogas operations involve pumping corrosive, hot or toxic fluids that need robust, reliable pumps.

2. How do FLOWELL™ and MACKPRO™ pumps differ?

FLOWELL™ is best for precision and versatility, while MACKPRO™ is engineered for harsher, high-temperature conditions.

3. Is it right for toxic liquids?

Yes. Both are specially created with features and materials that render them safe for handling poisonous and flammable fluids.

4. Are Mackwell pumps energy efficient?

Yes. Designs aim to optimize performance with minimized operating energy usage.