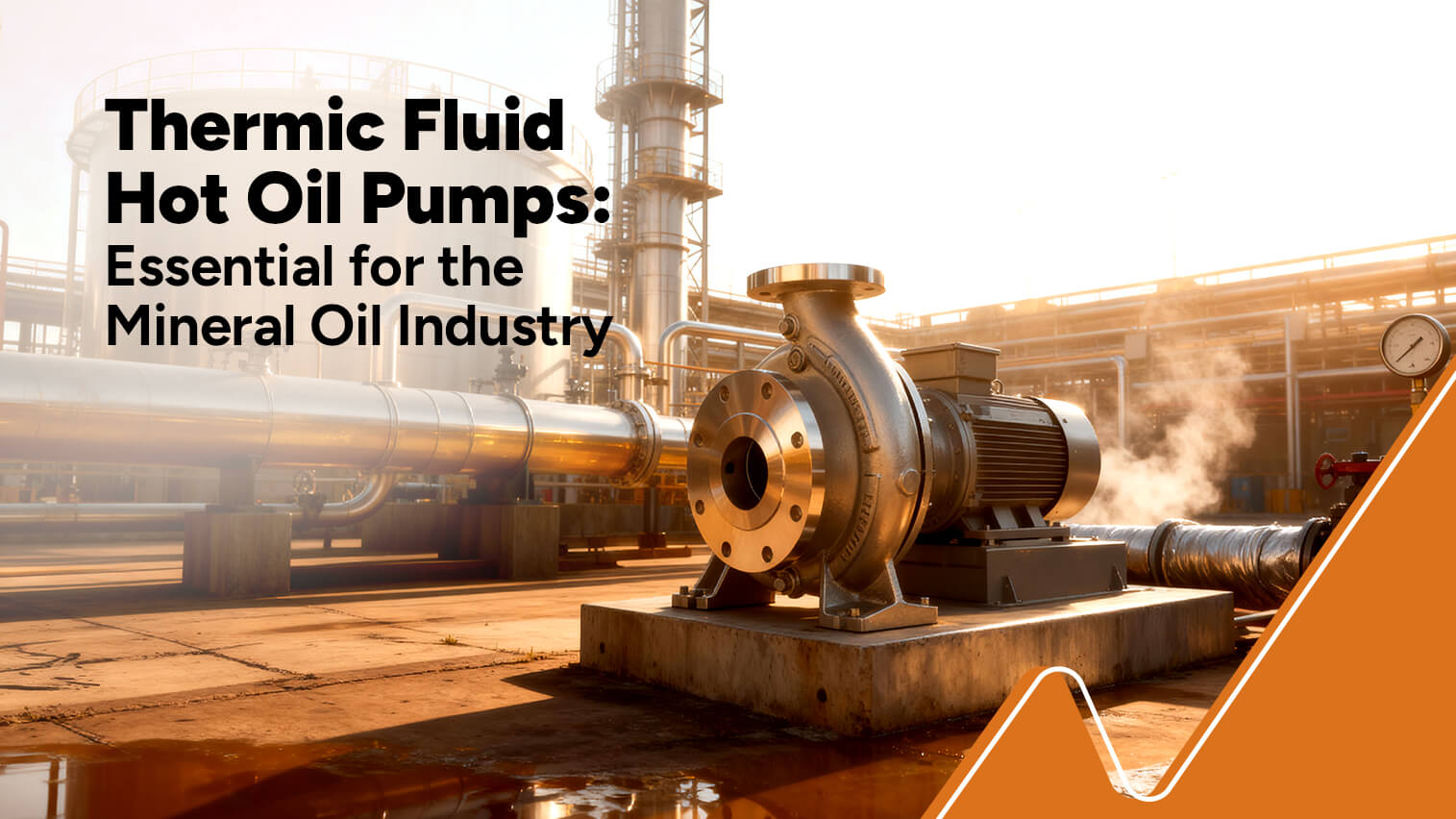

Thermic Fluid Hot Oil Pumps: Essential for the Mineral Oil Industry

You know how in a mineral-oil plant, when the temperature spikes and heat-transfer oils start pushing the system to its limits, everything hinges on one piece of equipment: the pump. When it works perfectly, you keep production running smoothly.

When it doesn’t, you’re looking at unscheduled downtime, compromised oil quality, or worse. That’s precisely why Thermic Fluid Hot Oil Pumps matter — and why we at Mackwell engineered the THERMACK ™ Hot Oil/Water Pump to answer that need in the mineral oil industry.

In this article, we’ll walk you through why these pumps aren’t a luxury, but a necessity, especially when your process involves mineral-based or synthetic thermal oils. We’ll cover what to look for, how the THERMACK stands out, and how you can apply it to your systems.

Why mineral oil systems need the right pump?

- Mineral oil or heat-transfer oil systems often run at very high temperatures — many fluids inclosed loop heating systems operate up to ~300 °C or more.

- If the pump can’t handle the heat or maintain proper flow you risk hot spots, fluid degradation, seal failures and higher maintenance costs.

- Also as the market for thermic fluids is expanding (especially in Asia-Pacific), plants need reliable pump solutions to keep up. For example: the thermic fluids market is projected to grow thanks to rising industrial heat-transfer applications.

- Therefore choosing the right thermic fluid hot oil pump manufacturers or hot oil circulation pump suppliers is crucial — it isn’t just about cost, but also reliability, flow capacity, material compatibility, and maintenance requirements.

What makes THERMACK ™ perfect for mineral oil based thermal systems?

We built THERMACK with your challenges in mind. Here’s how it matches up:

1) Wide temperature range

It operates from as low as -50 °C up to +350 °C without external cooling. That means whether you’re in a cold startup or full-throttle hot oil loop, THERMACK handles the span.

2) High flow and head capacity

With flow capacity up to 754 m³/h and head up to 102 m it suits large circulation loops typical in mineral oil processing.

3) No external cooling required

Many hot oil pumps require external cooling systems to protect bearings and casings. THERMACK uses internal venting and natural convection to dissipate heat less auxiliary equipment, lower maintenance.

4) Designed for oil and water

While the focus is hot oil, THERMACK also handles hot-water circuits. That flexibility allows you to standardize your pump inventory for multiple heat-transfer mediums.

5) Built to international flange standards

Flanges are manufactured in compliance with ISO 7005 PN16/PN20 or ANSI B16.5 150 lbs. The main purpose of this is to provide more compatibility with the current pipe work of mineral oil plants.

6) Hydraulics & shaft design optimized for thermal stress

The impeller is single-entry, closed, hydraulically thrust-compensated and dynamically balanced. The shaft is designed to minimize heat transfer into bearings — that means fewer failures, better uptime.

Where you’ll see THERMACK in action?

- In a refinery or mineral oil processing plant, hot oil may be circulated through heater bundles, exchangers, or reactor jackets. The pump underpins that loop.

- In a closed-loop thermal oil system for mineral-based fluids, THERMACK ensures that flow is maintained at high temperatures without cavitation or overheating of pump internals.

- If you are replacing a legacy pump or upgrading your system to higher throughput, THERMACK’s high flow and head capability make it a good choice.

- Where maintenance windows are tight and uptime is critical, the design features of THERMACK help reduce downtime and maintenance costs.

How to pick the right thermic fluid hot oil pump?

When evaluating pumps from hot oil pump manufacturers or selecting from hot oil circulation pump suppliers, here are key considerations — and THERMACK checks them off:

- Operating temperature range: Does it support your fluid’s max temperature? Mineral-oil based fluids often run 270-315 °C or more.

- Flow rate and head: Ensure the pump can deliver the required volume and pressure drop across your system. THERMACK supports up to 754 m³/h and 102 m head.

- Material compatibility: For mineral oils or synthetics, you’ll need materials that resist thermal stress, oxidation and chemical attack.

- Cooling requirements: An externally non-cooled pump that causes no trouble to the installation and reduces auxiliary costs is the one that THERMACK has designed.

- Maintenance & ease of service: One should recognize balanced impellers, low heat transfer to bearings, and industry-standard connections as key features.

- Supplier expertise and support: It will be a great advantage-working with a supplier who has the full comprehension of the hot-oil systems in mineral oil/heat transfer fluid units.

Conclusion

If you operate in mineral oil plant or any high-temperature, closed-loop heat-transfer system, investing in the right pump is not optional — it’s essential. The THERMACK ™ Hot Oil/Water Pump from Mackwell is engineered to meet your needs: high temperature, high flow, low maintenance, and no external cooling.

And when you partner with trusted “Hot Oil Pump Manufacturers” and “Hot Oil Circulation Pump Suppliers”, you’re investing in system uptime and long-term performance.

Feel free to explore more about the THERMACK on our product page right here, Thermack pump and if you’d like help choosing the right size or model for your system, we’re here to help.

FAQs

Q1: What differentiates thermic fluid hot oil pump from a standard pump?

A thermic fluid hot oil pump is a pump designed to handle high temperatures in a closed-loop system, utilizing thermal minerals or synthetic oils as the heat transfer fluid.

Q2: How important is the temperature range when selecting pump for mineral oil systems?

Very important. If your fluid runs at say 300 °C, you need pump rated beyond that and designed for it. If not you risk seal failure, bearing overheating, fluid degradation or pump downtime. Pumps like THERMACK with –50 °C to +350 °C capability give you margin.

Q3: Is it possible for one pump model to be used both for hot oil and hot water circulation?

Yes — providing the pump is rated for both and designed accordingly. On the label, we put THERMACK as a Hot Oil/Hot Water pump which means that we have designed it for use with both mediums. Such flexibility is a great way to lower redundant equipment needs.