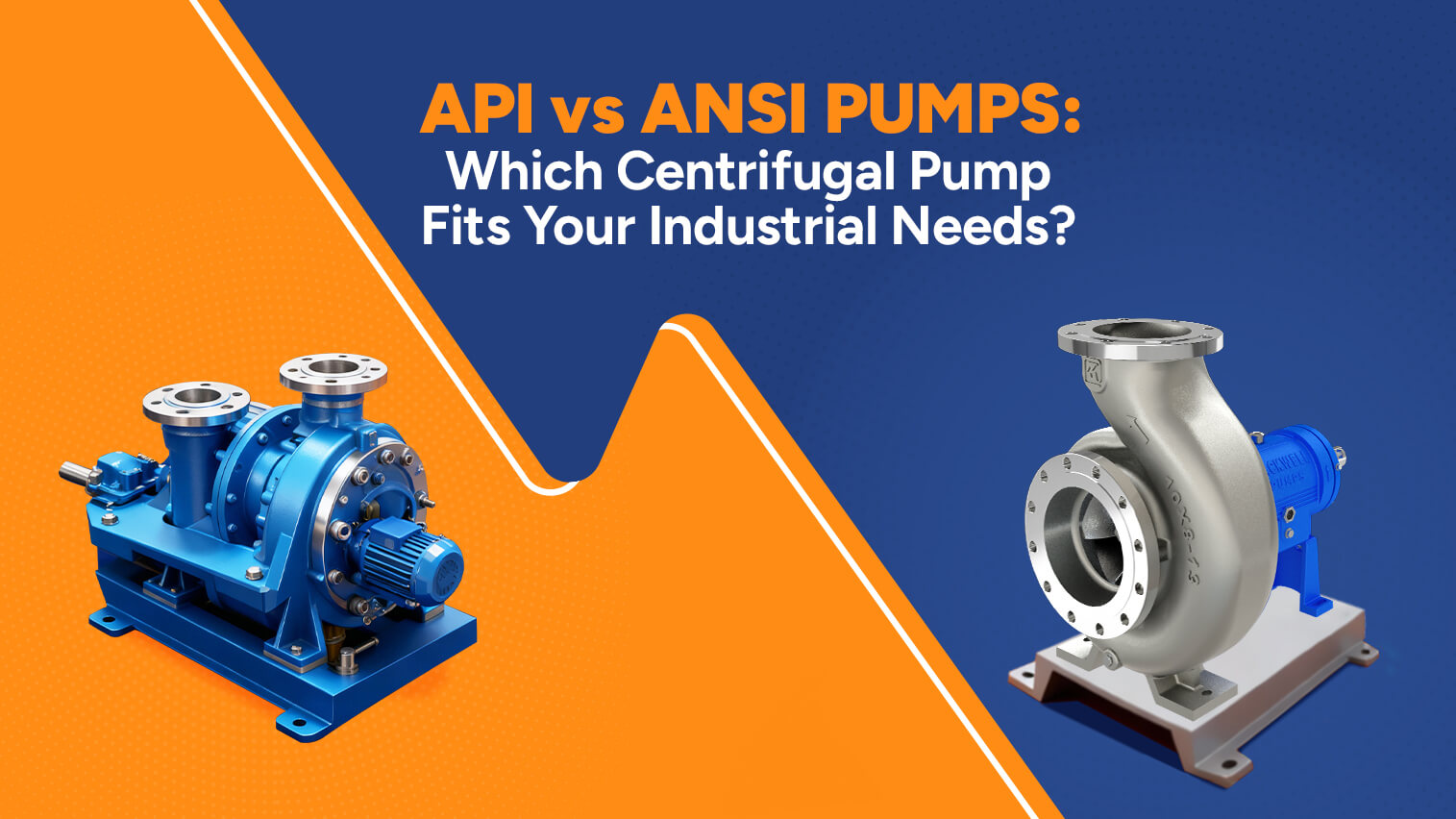

API vs ANSI Pumps: Which Centrifugal Pump Fits Your Industrial Needs?

If you are an industrial operator, you are likely aware that precision and reliability are crucial to business success. In fact, it is said that when toxic, flammable, or corrosive fluids are to be handled, the pump operator is the one who is in control of the safety and efficiency of the whole system.

That’s where the API vs ANSI Pumps discussion begins. Both standards define the design, manufacturing, and performance of a centrifugal pump, a comprehensive lineup, if you ask me. What each one of them does is pretty much the same but, interestingly, they serve in different verticals. So, knowing their dissimilarities will help you decide which one is more appropriate for your use.

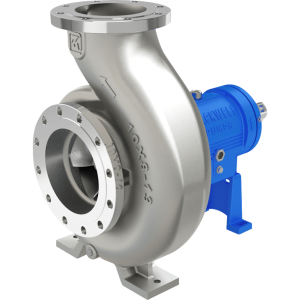

We at Mackwell, have developed two high-powered centrifugal pump series, namely: the FLOWELL™ Centrifugal Pump that is based on ISO and EN standards, and the MACKPRO™ Centrifugal Pump, which is beyond the ANSI/ASME B73.1 specifications. Each of them is the outcome of specific industrial work requirements, and we have the expertise to determine which one best meets your needs.

Let’s Start with the Basics: What Are API and ANSI Pumps?

- The operation of ANSI pumps is governed by the ANSI/ASME B73.1 standard. They are generally utilized in chemical processing, manufacturing, and other types of industries.

- API pumps follow the regulations of API 610 that is specifically targeted at petroleum, petrochemical, and heavy-duty refinery sectors.

In a nutshell, the main goal of ANSI pumps is to achieve interchangeability and efficiency, whereas API pumps are designed in such a way that their strength and safety aspects come to the fore in the most demanding conditions.

How API and ANSI Standards Differ?

Let’s break it down in simple terms:

1) Design Philosophy

- The main aim of the ANSI pump designers is the facilitation of the replacement procedure by normalization of the parameters of such pumps so that each one can be a mere substitute for the rest, regardless of the manufacturer from which one is procured.

- API pumps endure high pressures and extreme temperatures, as well as any other harsh environment commonly found in oil and gas applications.

2) Construction Strength

- API pumps are heavier and more robust. The primary source of emissions in refinery systems is where pump systems are used to handle liquids that are either toxic or flammable.

- Meanwhile, ANSI pumps are inherently simple, with minimal design details and parts; thus, they weigh less compared to the former and are the most efficient in terms of processing clean and slightly contaminated liquids.

3) Applications

- ANSI pumps are ideal for use in chemical, food, and general industrial applications.

- API pumps are preferred in refineries, petrochemical plants, and industries dealing with volatile fluids.

4) Maintenance and Cost

- ANSI pumps are more economical and easier to service.

- API pumps are more expensive but provide longer life in severe operating environments.

Where Mackwell Fits In: FLOWELL™ and MACKPRO™?

At Mackwell Pumps we don’t just build pumps, we build performance. Let’s explore where our centrifugal pumps stand out.

1) FLOWELL™ Centrifugal Pump

Our FLOWELL Centrifugal Pump is designed in accordance with ISO 2858 / EN 22858 (DIN 24256) standards, making it trusted choice for industries that demand consistency, reliability and high performance.

- Capacity: Up to 1500 m³/h

- Head: Up to 160 m

- Pressure: Up to 1600 kPa (16 bar)

- Temperature: From -50°C to +200°C

- Speed: Up to 3600 rpm

What makes FLOWELL unique:

- Numerous shaft sealing options for operational flexibility

- Available in various materials as per chemical compatibility

- Easy maintenance with high efficiency and proportional hydraulic performance

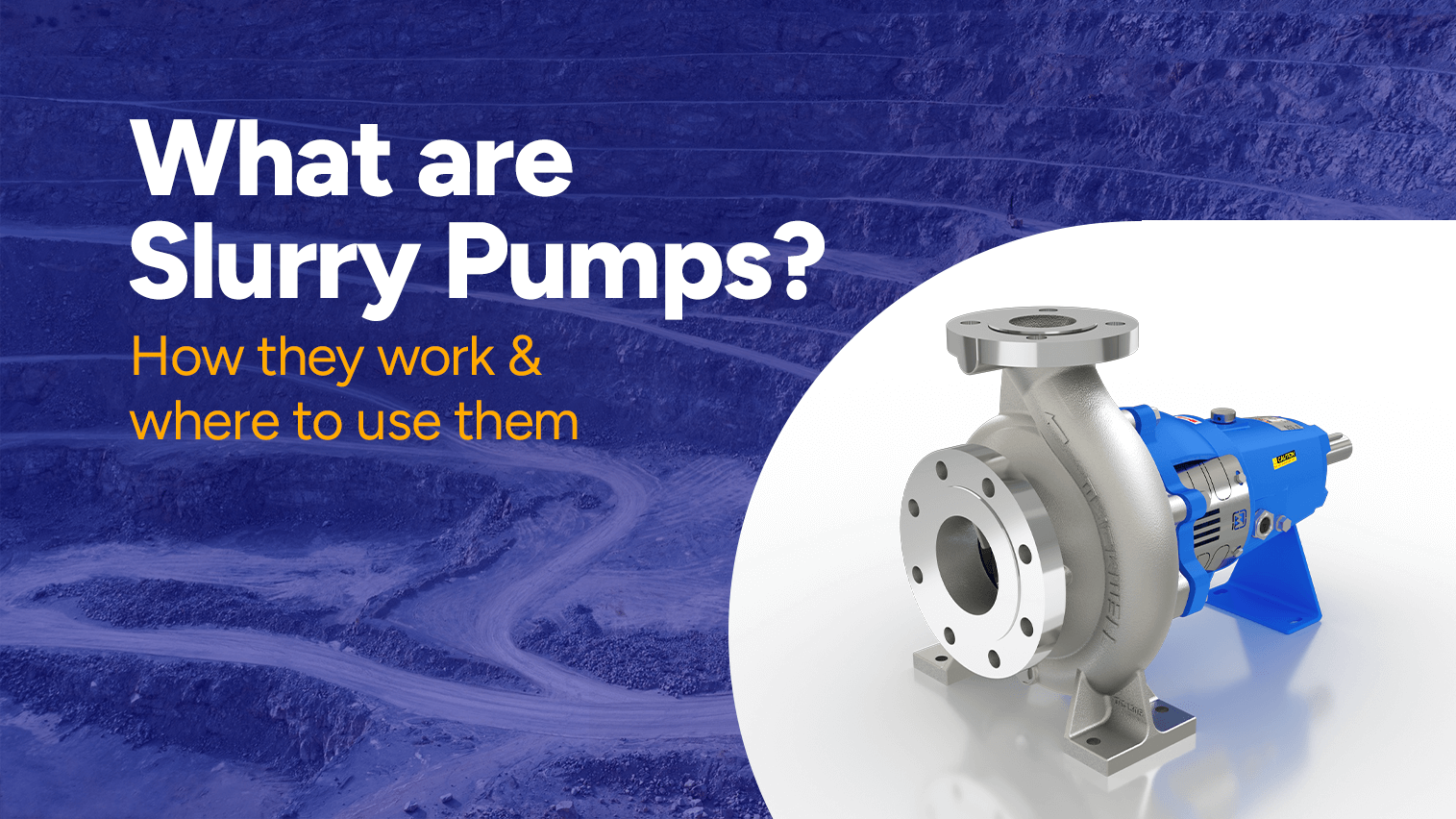

2) MACKPRO™ Centrifugal Pump

When you need something built for extreme conditions our MACKPRO™ Centrifugal Pump steps up. Designed to ANSI/ASME B73.1 standards, it’s the perfect example of what ANSI Centrifugal Pump Manufacturers strive to achieve: performance, durability, and flexibility.

- Capacity: Up to 1590 m³/h (7000 GPM)

- Head: Up to 223 m (730 ft)

- Temperature: Up to +260°C

- Speed: Up to 3600 rpm

What gives MACKPRO the edge:

- Rugged construction with Class 150 FF flanges for superior sealing

- Over 30 hydraulics to match system requirements

- Open impeller design for easy cleaning and high efficiency

As one of the leading ANSI Centrifugal Pump Suppliers we’ve built MACKPRO to handle whatever the chemical or refinery sector demands.

Choosing Between API and ANSI Standards

Determining the differences between these standards has never been so quick and simple:

- In case of any heavy-duty processes at your plant, including crude oil, natural gas, or petrochemical fluids related processes, an API-style pump is the right one to go with. This type of pump is a hard one, built for handling high-pressure, and is perfect for continuous, high-temperature operations.

- If your work involves usage of chemicals, solvents, or liquid transfer, then you should select an ANSI pump like MACKPRO or FLOWELL as it is the most efficient one. The main advantages of the pump are that it is energy-efficient, adheres to industry standards, and is relatively simple to perform maintenance operations on.

As per the most recent market report, the worldwide centrifugal pump market is projected to exceed USD 51 billion by 2030, with CAGR of 5.9%, which is result of the industrial growth and the need for highly efficient fluid handling equipment.

Conclusion

API or ANSI, both the pumps have their own merits; however, the deciding factor should be your process requirements. API pumps are designed for operation under great pressure in a potentially dangerous environment. On the contrary, ANSI pumps are designed for operation in chemical and other industrial environments where their other features, like standardization and efficiency, are needed.

At Mackwell, we’ve designed both solutions: the MACKPRO™ for demanding ANSI operations and the FLOWELL™ for general-purpose, ISO-standard efficiency.

Whether you need strength, flexibility, or precision, we have centrifugal pump that meets your specific flow requirements.

FAQs

Q1: What is the main difference between API and ANSI pumps?

API pumps are designed for the oil and gas industries; ANSI pumps are intended for use in the chemical and general industrial sectors.

Q2: Are ANSI pumps interchangeable?

Yes. ANSI pumps adhere to dimensional standard that enables interchangeability between different manufacturers.

Q3: Can a pump meet both API and ANSI standards?

Not typically. They serve different industry needs and follow distinct design and construction criteria.