Centrifugal Pumps for the Chemical Industry: A Complete Guide

One minor leak in a chemical plant is a very serious problem. That is why picking the right chemical centrifugal pump should be more than just about flow or pressure. In fact, it should also be about safety, reliability, and safeguarding the people, operations, and the environment.

At Mackwell Pumps, we collaborate directly with the chemical manufacturers who daily handle aggressive, toxic, and flammable liquids. We understand that when pumps fail, risks increase and operations are halted. This blog exposes the working of centrifugal pumps in the chemical sector and the role of the right design choice.

Why Pump Selection Is Critical in Chemical Handling Using Centrifugal Pumps

Chemicals are hardly ever simple. They may be corrosive, volatile, and cause dermatitis, or may be harmful when inhaled. Even a small transfer operation can lead to workers and equipment being spotted for risk.

Consequently, each pump for a chemical transfer has to work perfectly without any leaks, vibration, or abrupt breakdowns. Pumps are used in chemical plants for:

- Transferring chemicals from drums to tanks

- Circulating fluids inside reactors

- Feeding, filtration, or dosing systems

- Moving liquids between processing stages

Common Chemicals Moved Using Centrifugal Pumps

Chemical pumps are required to be capable of handling various kinds of liquids. However, all of them present a different challenge.

- Acids such as sulphuric or hydrochloric acid

- Alkalis, such as sodium hydroxide, are used in CIP cleaning

- Solvents such as toluene in adhesive production

- Pharmaceutical chemicals for processing

- Effluents and waste liquids requiring treatment

These fluids can change during processing. They may become hotter, more concentrated, or mixed with solids. That is where a well-designed industrial chemical pump becomes essential.

Why Centrifugal Pumps Are Widely Used in Chemical Plants

Essential reasons why chemical industries rely on centrifugal pumps:

- They provide a smooth, uninterrupted flow

- They are easy to operate and control

- They can handle large volumes effortlessly

- Their installation requires less space, thereby saving on floor area

- They incur less maintenance cost as compared to complicated ones

As the flow is without fluctuations, the process conditions stay unchanged.

How Centrifugal Pumps Improve Safety

Safety is not only about materials. It is also about how the pump behaves during operation. Centrifugal pumps naturally limit pressure when discharge valves are closed. This lowers the chances of damage to the system during the start-up phase.

At a chemical level, it means:

- Less possibility of a pipe bursting

- Less wear and tear on seals

- The movement of the fluid becomes controlled

- The system going down becomes quite predictable

This is just one of the several reasons why chemical industries have high confidence in centrifugal pump technology.

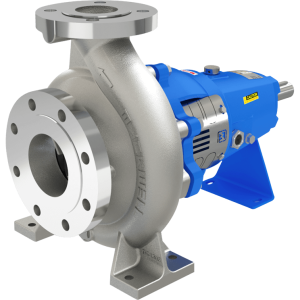

FLOWELL Centrifugal Pump for Chemical Applications

FLOWELL is our ISO 2858 and EN 22858 compliant centrifugal pump range. It is designed specifically for chemical and general industrial use. FLOWELL pumps are great for:

- Low viscosity chemical handling

- Conveyance of clean or slightly polluted liquids

- Continuous operation of the transfer process

Major benefits of FLOWELL:

- A wide variety of materials to choose from

- Diverse sealing systems available

- Excellent hydraulic performance for consistent output

- Simple upkeep with trouble-free operation for a long time

FLOWELL suits perfectly for chemical plants where the highlight is production.

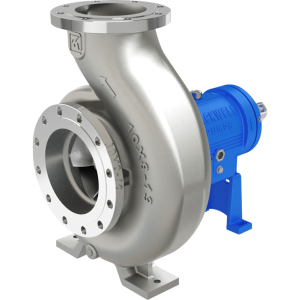

MACKPRO Centrifugal Pump for Harsh Chemical Duty

Some chemical processes demand more strength. That is where MACKPRO comes in. MACKPRO pumps meet ANSI and ASME B73.1 standards. Developed with the ability to manage toxic, flammable, and highly hazardous fluids, why manufacturing plants pick MACKPRO:

- Excellent durability for tough environments

- The open impeller is meant for high efficiency.

- Extensive hydraulic range

- Resist thermal shocks and perform as expected

The refining and petrochemical sectors are the most probable locations to find the MACKPRO pump, where no failure is acceptable.

Chemical Industry Trends and Pump Demand

Worldwide, the chemical industry goes straight on an upward trajectory. According to the data from the American Chemistry Council, the global chemical production is going up at a rate of 3-4% annually. Such a rise in the output level makes it necessary to have reliable pumps that can safely and effectively handle complicated fluids. As plants become larger, the issue of pump dependability becomes even more vital.

Final Thoughts

A major component of chemical processing systems is centrifugal pumps. They facilitate the safe, steady, and cost-effective flow of hazardous chemicals. Protecting people, plants, and production objectives of a facility begins with choosing the right chemical centrifugal pump.

Whether you require a multi-purpose product such as FLOWELL or a robust performer like MACKPRO, Mackwell Pumps provides models that you can rely on.

FAQs

1) What makes centrifugal pumps a common choice in chemical plants?

They provide a constant liquid flow, are easily controllable, and offer a safer operation for harsh and dangerous liquids.

2) Are centrifugal pumps suitable for handling strong chemicals?

Absolutely, when they are equipped with appropriate materials and sealing systems, they are capable of chemical duty operation.

3) What is the difference between FLOWELL and MACKPRO?

FLOWELL suits general chemical transfer, while MACKPRO is designed for harsher and more demanding applications.