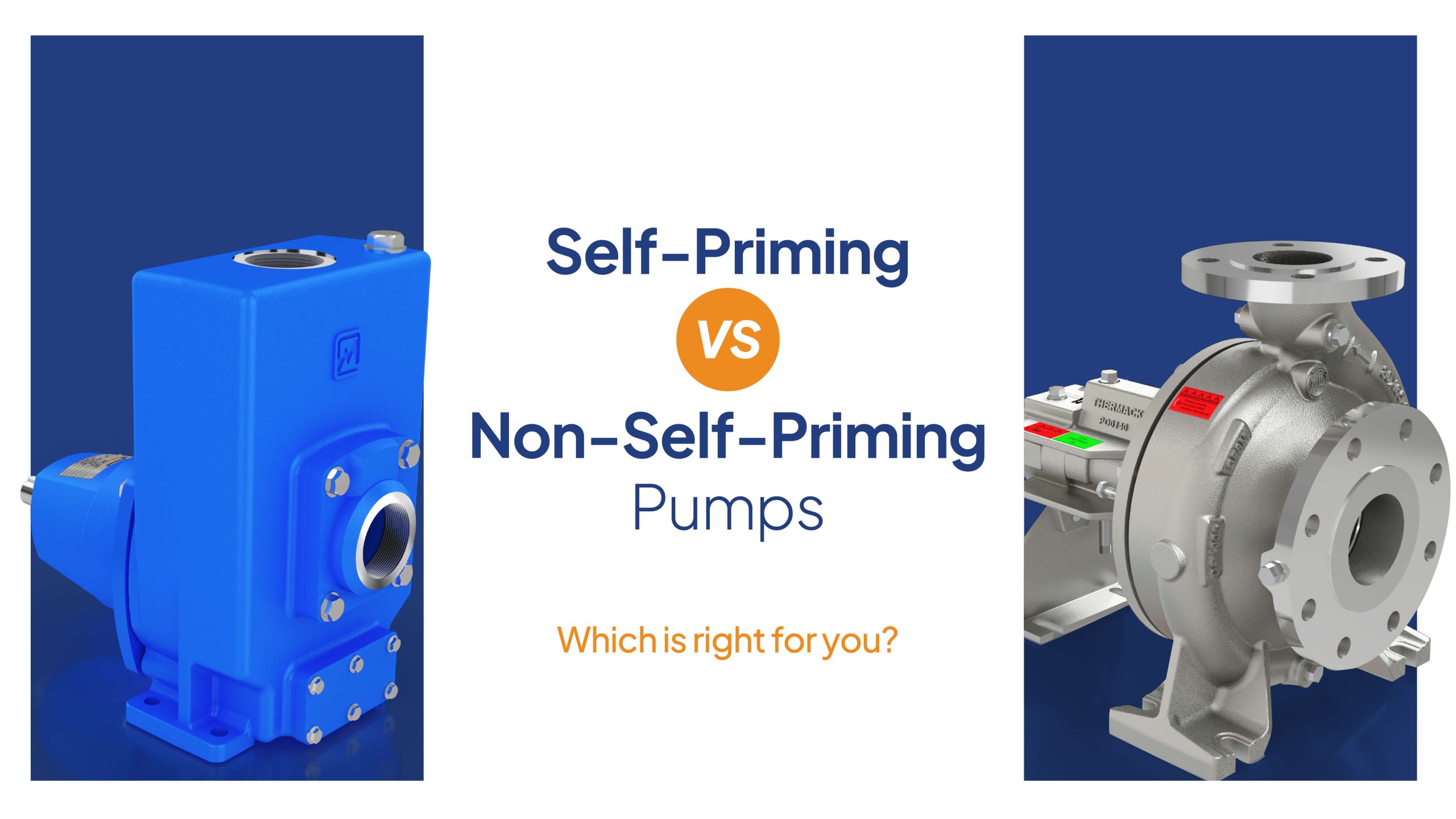

Self-Priming Pumps vs. Non-Self-Priming Pumps: Which is right for you?

Confused between self-priming and non-self-priming pumps? This article explains the key differences in functionality, installation, and application. Self-priming pumps are ideal for quick starts and handling air in the suction line, perfect for intermittent use. Non-self-priming pumps require manual priming but are efficient for continuous, submerged operations. Learn which pump suits your system based on ease of use, maintenance, and water source conditions. Discover which is better for your needs: self-priming or non-self-priming pumps.

When you try to define the difference between self-priming and non-self-priming pumps, you will know that both of them have basic differences. Self-priming pumps are convenient machines that can pull in air and ready themselves to start without human help. In contrast, non-self-priming pumps require manual priming or a flooded suction to start, similar to how a car does not turn on until you push it. But these pumps differ in many ways.

Self-Priming Pumps vs. Non-Self-Priming Pumps

Self-Priming Pumps

- How do they work? These pumps start by trapping liquid in the internal chamber, mixing it with air, and then expelling it to prime themselves.

- Benefits: These pumps do not require priming and are nearly perfect for intermittent or above-ground setups. Additionally, they excel in handling air and gas bubbles, making them perfect for portable and remote applications.

- Cons: These machines are unsuitable for high-pressure tasks due to their fragility and lower efficiency compared to non-self-priming models. They will also require a higher initial cost to buy.

Non-Self-Priming Pumps

- How do they work? These pumps rely on either a flooded suction model or external priming to begin moving fluid, which means they function similarly to pumps requiring a full tank.

- Benefits: These machines often prove themselves more efficient and objectively better at jobs that require high flow and consistency. They are also generally cheaper and have simpler designs, so they are easy to repair and great for systems requiring a consistent liquid supply.

- Disadvantages: This system requires a priming setup or flooded suction, which increases the steps required to start the device. But the bigger problems are that it struggles a lot when air bubbles get stuck inside it or if it is trying to start dry. These machines are also much less flexible for variable conditions and do not have the luxury of being portable.

Applications of Self-Priming Pumps vs Non-Self-Priming Pumps

Self-priming pumps are useful in situations requiring construction dewatering, emergency flood response, and wastewater transfer because they are easy to start without requiring manual labor and handle air and debris in unpredictable conditions with full efficiency.

Their incredibly portable and self-sufficient designs make them perfect for removing water in messy, portable situations like firefighting or irrigation systems.

Non-self-priming pumps work amazingly in water treatment plants, HVAC systems, and industrial coolers. They are efficient machines for consistent duties requiring high flow and a steady supply.

Despite their simple design and cost-effectiveness, non-self-priming pumps excel in fixed setups where priming is effortless, ensuring smooth operations and financial stability.

How will you choose the right pump?

When choosing between self-priming and non-self-priming pumps, remember a few things.

- Suction setup: The configuration of your suction system significantly influences your choice between self-priming and non-self-priming pumps. If they are above ground and have variable levels, you are better off going with self-priming. But non-self-priming pumps will do just fine if you are working on flooded suction setups.

- Portability: Non-self-priming setups are not portable. Meanwhile, self-priming pumps can be very portable and handle dirty water and air bubbles incredibly well, making them a worthwhile solution for portability.

- Budget: Budget does not matter because both pumps may pose similar strains. A non-self-priming pump is not as expensive as a self-priming pump, but it consumes more electricity in the long run.

- Duty cycle: If your system requires a constant stream of high flow, you can easily work with non-self-priming setups, but if the situation is intermittent and tricky, a self-priming pump can save you a lot of hassle.

Some pro tips for maintaining your pump

- First, you should be sure that wherever you place your pump, it can handle the lift weight. Pumps can usually handle a decent height of 25 feet with ease.

- You should also invest in a check valve, which is very useful if you get a self-priming pump to maintain prime when you turn the system off and on again.

- If you are still adamant about using a non-self-priming system for your requirements, ensure a reliable priming system, such as a foot valve or a flooded inlet.

- You should always have the right pumps to handle the fluids you are cycling through. Corrosive fluid can harm many metals and eventually cause the pump to fail and shut down. Ask your manufacturer to build your pump with the right materials.

Conclusion

Now that you know everything about self-priming and non-self-priming pumps, we hope you can make a better decision when purchasing a Mackwell pump. Remember that neither option is superior in this context, as both machines provide distinct functionalities suited to different situations. The priming method is more than just a feature; it influences numerous aspects that have the potential to positively or negatively impact any situation you encounter.