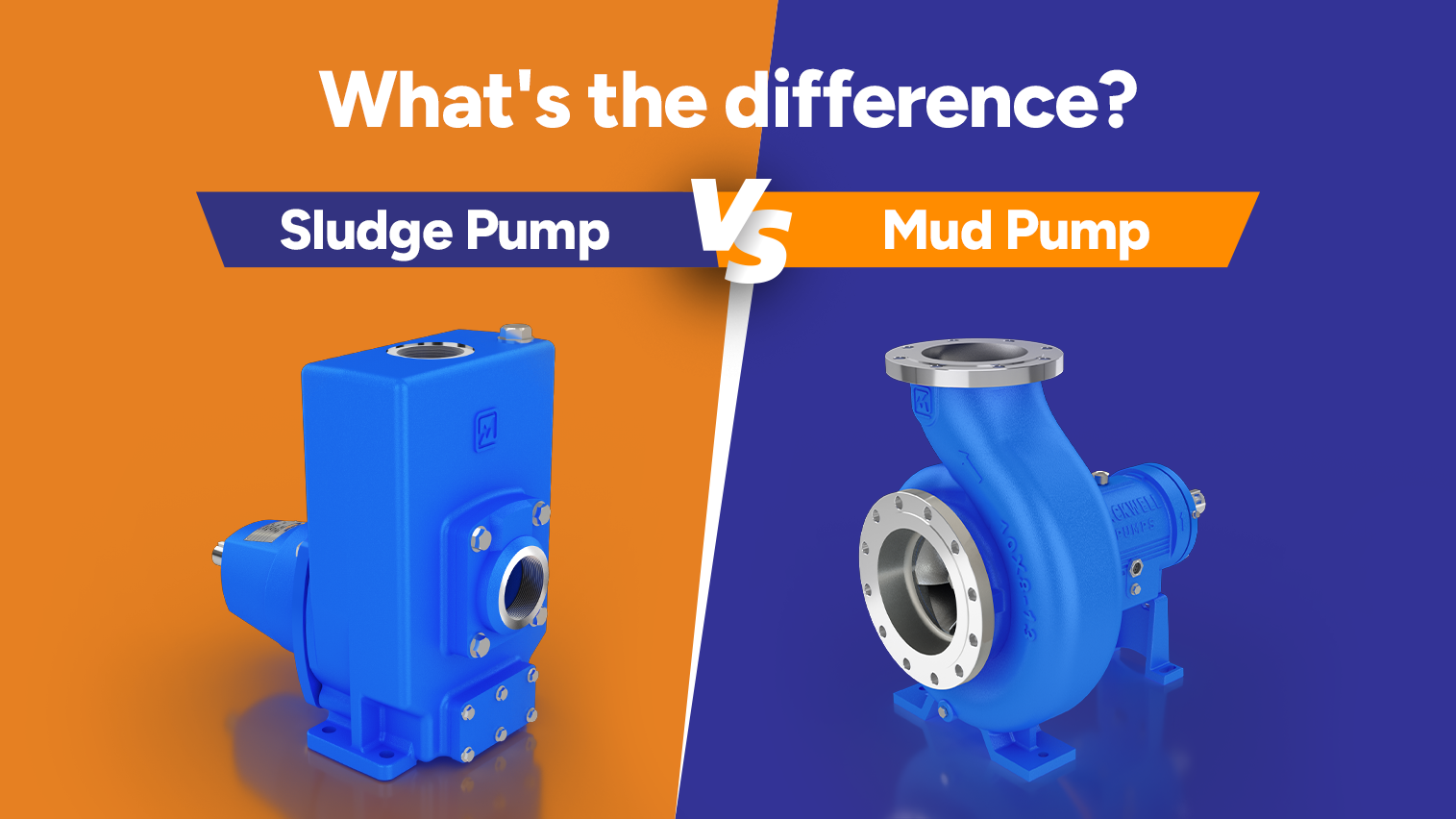

Sludge Pump vs. Mud Pump: What’s the Difference?

Ever found yourself wondering what sets a sludge pump apart from a mud pump? You’re not alone.

At first glance, both do the same job: move heavy, viscous fluids. But dig little deeper, and you’ll find crucial design, usage, and performance differences.

As one of the leading Sludge Pump Manufacturers in India, we at Mackwell Pumps are here to break it down for you in the simplest, clearest way. And yes, we’ll tell you when to use what without the fluff.

Let’s clear the mud and make sense of it all!

What is Sludge Pump?

Sludge pumps are designed to handle thick, viscous fluids filled with semi-solid waste—often from industrial or wastewater treatment processes.

- Think of sludge as that heavy, sticky material from ETPs, STPs, or after a filter press cycle.

- These pumps are meant to push this dense mix with minimal clogging.

- They’re made to withstand abrasive solids and high-pressure conditions.

At Mackwell, our MMSP series of sludge pumps, with mechanical seals, is a reliable choice for filter press feeding and ETP applications.

What is Mud Pump?

Mud pumps, on the other hand, are typically used to transport water mixed with soil or sediments, which you’d find on construction or mining sites.

- Mud is thinner than sludge but still gritty.

- Mud pumps are great for dewatering trenches, borewells, or underground works.

- While rugged, they don’t require the same resistance to semi-solid loads as sludge pumps.

This is where the confusion begins. But now you know: mud ≠ sludge.

Differences: Sludge Pump and Mud Pump

Let’s get this straight with some compare-and-contrast basics:

- Material handled: Sludge pump moves thick, semi-solid waste. Mud pump moves water mixed with sediment.

- Applications: Sludge pump suits ETP, STP, and filter press duty. Mud pump suits mining, construction, and drilling.

- Pump strength: Sludge pump has higher pressure tolerance for dense media. Mud pump offers moderate pressure for watery mixes.

- Clogging resistance: Sludge pump shows excellent clog resistance. Mud pump has moderate resistance.

- Examples: Sludge pump example is the MMSP Series. Mud pump example is site dewatering pumps.

So, the next time you compare sludge pump vs. mud pump, remember it’s not where you’re pumping it, but what you’re pumping.

Why Mackwell Pumps Make the Difference?

We design solutions for toughest industrial environments. Check the attributes:

MMSP Series – Our Sludge Champion

- Specifically designed to withstand clogging when dealing with heavy sludge duty.

- Perfect for continuous use in filter press systems.

- Consistent performance in even high viscosity.

PRIMEWELL – The Self-Well Star

Need a self-priming pump to easily handle dewatering, sludgy water or construction drainage? Meet PRIMEWELL™ an 8-meter suction head radial impeller centrifugal pump that can tackle the toughest conditions.

- Flow rate up to 280 m³/h

- Head up to 60 meters

- Temperatures up to 95°C can be handled

- Pressure limit? A robust 16 bar

PRIMEWELL is tested and proven to be a safe and easy choice for sewage bypass or slurry transfer, such as water.

Find out more about PRIMEWELL here.

Selecting the Right Pump – When to Use What?

Here’s a brief guide to assist you:

Use a sludge pump if:

- You have heavy sludge with high solid loadings.

- You are feeding a filter press.

- You are in an ETP or STP plant.

Use a mud pump if:

- The liquid is sandy with a small amount of dirt.

- You’re working on site drainage.

- Fast setup and velocity are more issues than density control.

Still unsure? We’re a call away. We assist industries in making better choices day by day.

Real-World Applications We Serve

- Effluent Treatment Plants

- Sewage Pumping

- Construction Dewatering

- Industrial Waste Management

- Chemical Slurry Transfer

That’s why we’re happy to be relied upon as Sludge Pump Suppliers in India and Mud Pump Manufacturers in India for various industries throughout the country.

Want to Learn More?

A thought-provoking report by Statista depicts how industrial water and sludge requirements are surging in India—primarily in the textile, food, and metal sectors. That implies innovative pump solutions are no longer advisable—they’re a necessity.

Final Thoughts

When comparing Sludge Pump vs. Mud Pump, it’s not which is preferable, but which is preferable for your needs.

At Mackwell Pumps, we don’t just build pumps that move fluid—better, we build pumps that drive your business.

Maybe it’s the rugged MMSP series or the intelligent, self-priming PRIMEWELL—you’re in good hands.

FAQs

Q1. Will a mud pump pump sludge?

No. Sludge needs more pressure and an unclogged flow path. Mud pumps are not designed to handle trash that’s half-soldier.

Q2. What is the suction lift of the PRIMEWELL pump?

PRIMEWELL has an effective handling of up to 8 meters of suction head.

Q3. Is a sludge pump or a mud pump more energy efficient?

That depends on the application. In the case of heavy material, sludge pumps are efficiency engineered.

Q4. Are Mackwell pumps easy to maintain?

Yes! Maintenance is quick and tool-friendly, particularly with our back-pull-out designs, such as PRIMEWELL.