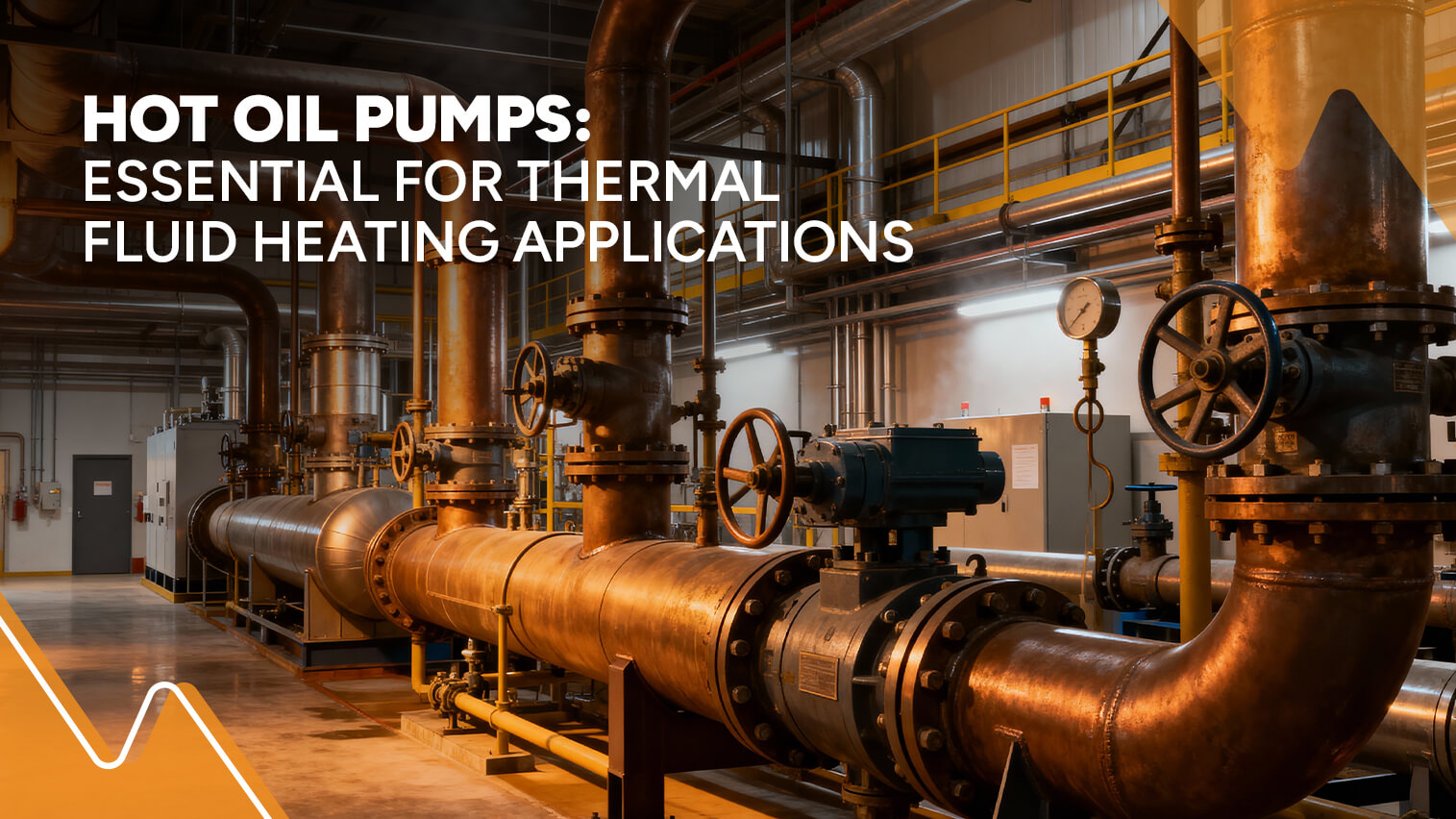

Hot Oil Pumps: Essential for Thermal Fluid Heating Applications

In high-temperature operations, there is no room for failure. When heat drives the process, flow becomes the backbone of safety and efficiency.

That is the reason why the design aspect is given so much attention by hot oil pump manufacturers, especially when it comes to designing precision, material strength, and thermal control.

At Mackwell Pumps, we engineer hot oil pumps that handle extreme heat without losing stability, performance, or reliability.

Why Hot Oil Pumps Matter in Thermal Systems

Thermal fluid systems operate under constant heat stress. In doing this, oil or water should be allowed to circulate freely while maintaining the required temperature. If there is any disruption, it may result in:

Any disruption can cause:

- Uneven heating

- Energy loss

- Equipment damage

- Safety risks

Therefore, it becomes the case that a hot oil pump for thermal fluid heating systems is a must-have rather than a maybe one.

Understanding Thermal Fluid Circulation

The pump in thermal systems is not only responsible for liquid movement. It also prevents the overheating and pressure imbalance of the system. A carefully crafted hot oil pump makes sure of:

- Fixed circulation at elevated temperatures

- Minimum heat transfer to bearings

- Non-stop functioning even without external cooling

These are the main factors that influence the uptime of the plant and its running cost.

Introducing THERMACK: Built for Extreme Heat

We introduced the THERMACK product line to excel in the most challenging environments of the thermal industry. It is engineered to handle mineral and synthetic thermal oils up to 350 degrees Celsius.

We designed THERMACK to perform reliably without external cooling systems. This reduces complexity and improves long-term reliability.

What Makes THERMACK Different

THERMACK is not a modified standard pump. It is purpose-built for thermal fluid circulation. The key engineering features of the device include:

- Internal venting mechanisms that provide extremely fast heat dissipation

- Carrying out cooling through natural convection from the casing to the bearing

- The design of the shaft that minimizes the heat

These capabilities alone could be enough to extend the life of the components, but the THERMACK also contains a protective seal system that guarantees ultimate protection against the ingress of foreign substances. Furthermore, it provides additional sealing support that helps during overpressure situations.

Performance That Supports Demanding Processes

THERMACK pumps are a dependable solution for providing a steady flow even when subjected to extreme conditions. Their main operating capabilities began with:

- Volumetric flow up to 754 cubic meters per hour

- Head up to 102 meters

- Working temperature range from -50 to +350 degrees Celsius

This justifies the utilization of the THERMACK pump for hot oil and hot water circulation purposes.

Designed for Safety and Stability

Safety is central to thermal systems. THERMACK incorporates design features that reduce operational risk. Pump features include:

- ISO 7005 PN 16 or PN 20 flanges

- ANSI B16.5 Class 150 compatibility

- Single-entry closed impeller with hydraulic thrust compensation

- Dynamic balancing for vibration-free operation

Reliable venting during operation ensures pressure stability at all times.

Where THERMACK is Commonly Used

THERMACK supports industries where heat transfer reliability is critical. Typical applications include:

- Thermal oil heating systems

- Hot water circulation loops

- Industrial heat exchangers

- Process heating units

These systems rely on continuous, safe circulation to maintain output quality.

Energy Efficiency and Industry Trends

According to the International Energy Agency, industrial heat accounts for nearly 74 per cent of industrial energy demand worldwide. Efficient circulation pumps play a key role in reducing energy losses in these systems.

This growing focus on efficiency is why many hot oil pump suppliers are relying on purpose-built thermal pumps instead of modified standard designs.

Why Engineers Choose Mackwell Pumps

At Mackwell Pumps, we design with application reality in mind. We don’t add complexity unless it improves performance or safety. We are the engineers’ first choice when they need:

- Well-organised thermal design

- An operation that is consistent even at very low or very high temperatures

- Good quality of materials

- Assistance at all stages: from specification to commissioning

By applying this strategy, we have been able to establish long-lasting relationships with partners worldwide.

Selecting the Right Hot Oil Pump

Trying to find the best hot oil pump, you must consider:

- The maximum temperature at which the unit will be operated

- The kind of liquid and its viscosity

- The quantity of fluid to be pumped at its pressure

- The standards that the installation has to meet

With the correct design, the pump will become an invaluable piece of equipment as it reduces the chances of breakdown and increases plant safety over time.

The Role of THERMACK in Modern Thermal Systems

THERMACK is the ideal component for modern thermal systems that require:

- The capability of being operated at a very high temperature

- A good performing piece with only a few small issues or maintenance tasks over a long period

- Keeping the flow rate constant

- Its use and its maintenance are safe for the operator

The concept behind it is that it should be very energy-efficient, without vibrations, and very reliable during long working periods.

Looking Ahead in Thermal Fluid Engineering

As thermal system performance standards continue to rise, the reliability of equipment, particularly pumps, becomes increasingly critical. To meet the challenges of elevated temperatures and tighter safety regulations, the solutions need to be more intelligent.

Mackwell Pump is not taking the challenge lightly. We are constantly enhancing our thermal pump designs to provide customers with reliable and expert solutions for their needs.

FAQ’s

1) In what temperature range can THERMACK work?

THRMACK supports a variety of operating temperatures, ranging from -50 degrees Celsius to 350 degrees Celsius.

2) Is external cooling necessary for THERMACK?

Not at all, THERMACK is constructed in a way that it doesn’t need any external cooling units to function.

3) Can THERMACK be used as a heater for thermal oil and hot water?

Yes, it is designed to be utilized in heating both thermal oil and hot water.

4) What are the common industrial applications of hot oil pumps?

Hot oil pumps are the backbone of any thermal processing, chemical manufacturing, and industrial heating systems.