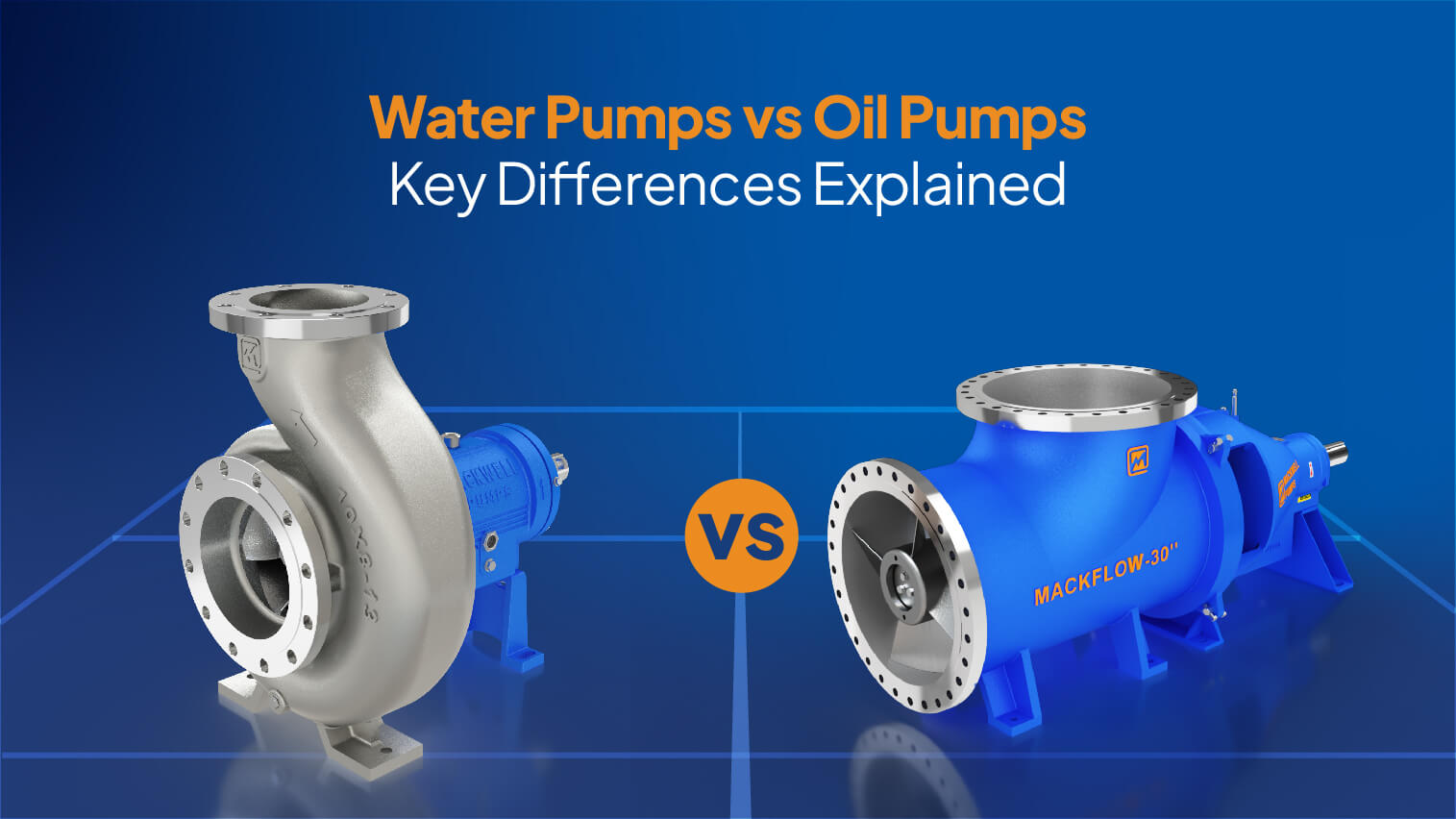

Water Pumps vs Oil Pumps: Key Differences Explained

Choosing the right pump involves technical considerations but is also about safety, efficiency and long-term operating cost.

Here, we explain the differences between water pumps and oil pumps in a straightforward manner. We also explain the difference between an oil pump and a water pump, so you can match the pump to the actual working conditions, not just the fluid type.

At Mackwell Pumps, we design solutions like the THERMACK pump for demanding heat transfer systems where ordinary pumps fail.

Why Understanding Pump Differences Matters

Water and oil behave very differently inside a pump. Using the wrong pump can lead to seal damage, bearing failure, or unsafe overheating.

We keep hearing about the system’s breakdown, not due to ignorance of maintenance, but because the pump was not selected according to the fluid temperature and its properties. This is where understanding the difference between water pumps and oil pumps becomes critical.

What is a Water Pump Designed For

Water pumps are made for free-flowing fluids. They are generally used for cold or moderately heated water. Typical features include:

- Simple sealing arrangements

- Materials chosen for corrosion resistance

- Operation at lower temperatures

Water pumps are ideal for cooling systems, water circulation, and utility services. They are not meant to handle extreme heat or thermal oils.

What is an Oil Pump Built To Handle

Oil pumps deal with thicker fluids and higher temperatures. Thermal oils expand, retain heat, and behave differently under pressure. Oil pump designs focus on:

- Controlled heat transfer away from bearings

- Special shaft and seal design

- Materials that resist thermal stress

This is a major difference between an oil pump and a water pump that cannot be ignored.

Temperature Handling is the Biggest Difference

Water pumps typically operate well below the boiling point. Oil pumps are designed for much higher limits. THERMACK, for example, works safely from minus 50 degrees up to 350 degrees.

This range is impossible for standard water pumps without external cooling. That temperature capability alone defines most real-world use cases.

Fluid Properties Change Everything

Water flows easily and cools components naturally. Oil moves more slowly and holds heat longer. Because of this:

- Water pumps rely on fluid cooling

- Oil pumps rely on internal venting and heat control

THERMACK utilises innovative internal venting technology that enables heat to dissipate from bearings through natural convection. This design avoids the need for external cooling systems.

Internal Design Differences You Should Know

The internal construction of pumps tells the real story. Water pump design usually includes:

- Standard impellers

- Conventional bearing housing

- Basic shaft design

Oil pump construction focuses on:

- Closed, dynamically balanced impellers

- Hydraulically thrust-compensated design

- Shafts engineered to reduce heat transfer

This engineering difference ensures long life at high temperatures.

Where Water Pumps Are Commonly Used

Water pumps are widely used in:

- Cooling towers

- Water circulation loops

- Utility supply systems

- Low-temperature industrial processes

They are reliable when used within their limits. Problems begin only when they are pushed into thermal oil duties.

Where Oil Pumps Are Essential

Oil pumps are critical in:

- Heat transfer systems

- Hot oil circulation loops

- High temperature process heating

- Thermal fluid boilers

THERMACK is specifically designed for these applications. It handles both hot oil and hot water without design compromise.

Safety and Reliability Considerations

Oil systems carry a higher risk due to temperature and pressure. A pump failure can cause serious downtime or safety incidents. Oil pumps, therefore, require:

- Strong flange standards

- Reliable venting

- Stable bearing temperatures

THERMACK meets ISO 7005 and ANSI flange standards to ensure system integrity.

Energy and Efficiency Perspective

According to the U.S. Department of Energy, pumps account for nearly 20 per cent of global motor-driven electricity usage in industrial systems.

Using the right pump type improves efficiency and reduces energy loss caused by overheating and friction. This is another practical reason to respect the difference between an oil pump and a water pump.

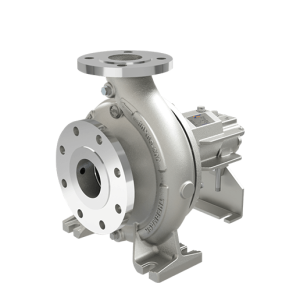

THERMACK Pump as the Right Oil Pump Solution

At Mackwell Pumps, THERMACK is built for real heat transfer challenges. Key highlights include:

- Flow up to 754 cubic meters per hour

- Head up to 102 meters

- Operating range from minus 50 to plus 350 degrees

- No external cooling required

It is engineered specifically for mineral and synthetic thermal oils. You can explore the full THERMACK pump details here!

Final Words

Water pumps and oil pumps may look similar on the outside. Inside, they are built for very different jobs. Understanding water pumps vs oil pumps is about safety, performance, and long-term reliability.

Failing to distinguish between an oil pump and a water pump can lead to premature failure and increased operating costs. For high-temperature systems, a purpose-built solution like THERMACK is not optional. It is essential.

FAQs

1) Is it possible to use a water pump for hot oil?

Water pumps are not designed for high-temperature oils; thus, they can be damaged quickly.

2) What is the main difference between a water pump and an oil pump?

An oil pump is capable of handling high temperatures and viscous fluids since it is internally designed to such specifications.

3) Does THERMACK need external cooling?

No. THERMACK uses internal venting to manage heat naturally.

4) Where are hot oil pumps commonly used?

They are used in heat transfer systems, thermal fluid heaters, and hot oil circulation loops.